THE CONNECTED TWIN

YOUR DIGITAL REPRESENTATION FOR OPERATIONS, PLANNING & MAINTENANCE

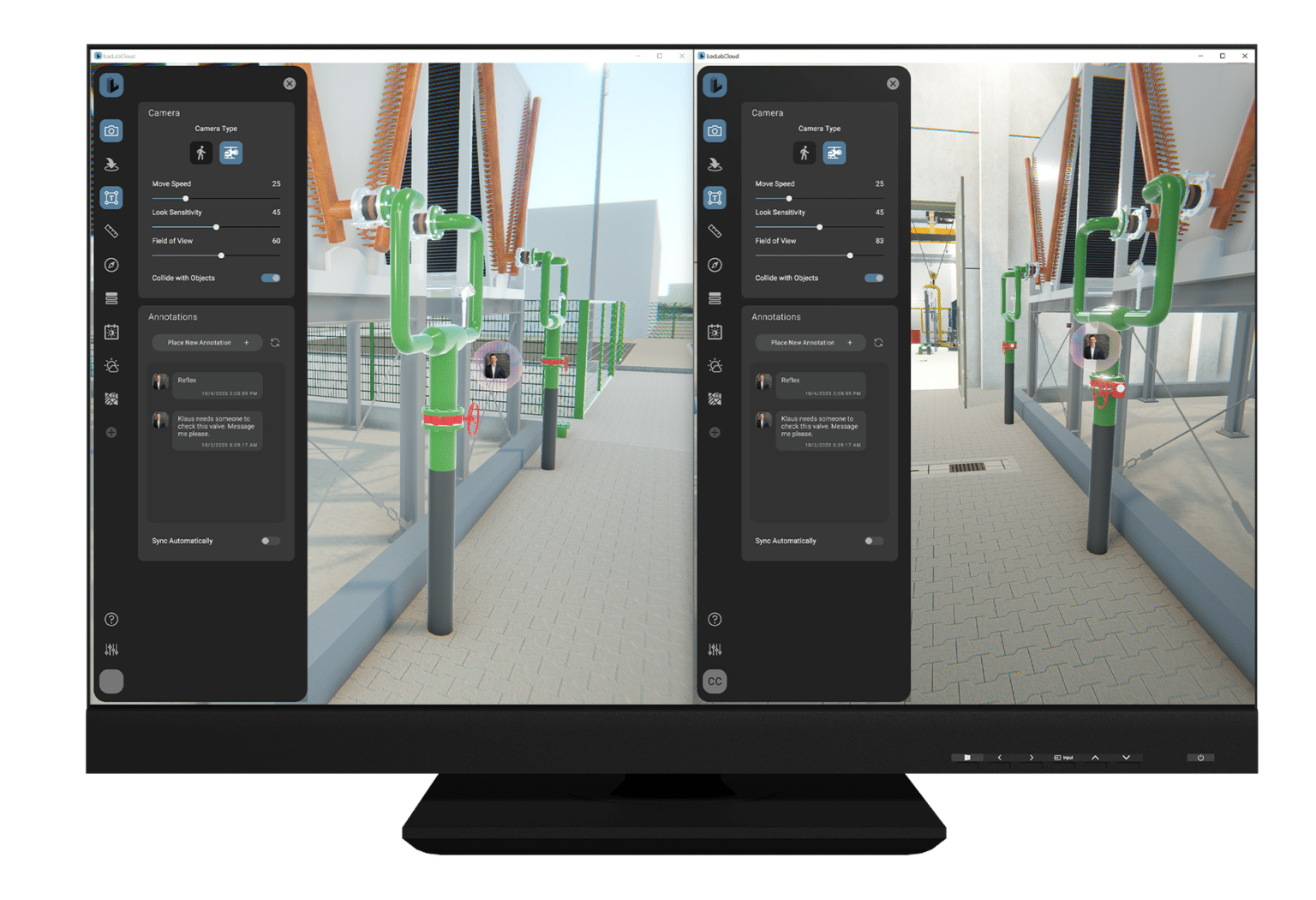

Your 3D model becomes a Connected Digital Twin when operational data, sensor values, and documentation sources are linked to it.

This creates a single, intuitive environment where teams can make faster, safer, and more informed decisions.